BLASTRAC

The Blastrac-EBE blast cleaning machines for steel surfaces are designed for processing large areas

on vertical or near vertical surfaces. The machines are suspended from either a crane or a rigging

system and operate in an up or down direction to clean and profile steel tanks or ship hulls. They are

remotely controlled from a mobile work station.

The working principle of all Blastrac-EBE equipment is based

on the laws of kinetic and mechanical energy. The cleaning

operation is performed by steel abrasive being thrown at high

velocity against the surface to be cleaned. Throwing action is

achieved through centrifugal force, where a wheel with blades

located radially is rotated at high speed. On to this revolving

wheel, abrasive is fed in such a manner that it travels along

the radial length of the blades and then is thrown off in a high

velocity stream at the surface to be cleaned, efficiently blast

cleaning the work surface. After the abrasive has impacted

the work surface, it rebounds back into the machine, taking the rust and old coating debris with it. Inside the machine the abrasive is separated from the dust and debris. The abrasive is returned to the abrasive storage hopper to be re-used. The debris is transported by air flow into the dust collector, where it is collected and packed into containers for disposal. This process is an on-going and automatic continuous operation. A system of especially designed magnets, specifically arranged and attached to the machine, pull against the steel work surface. By this means the machine is maintained in close contact with the work surface, thus ensuring that abrasive loss and dust emissions are kept at a minimum. This allows the

machine to operate in close proximity to other process functions and follow on painting procedures can continue without loss of time.

Horizontal Blast Cleaning Machines for Steel

The dust free blast-cleaning equipment of Blastrac-EBE is especially designed for use in shipyards

and in the petrochemical industry, where its use replaces traditional open blast cleaning operations.

The working principle of all Blastrac-EBE equipment is based on the laws of kinetic and mechanical

energy. The cleaning operation is performed by steel abrasive being thrown at high velocity against the

surface to be cleaned.

Throwing action is achieved through centrifugal force, where a

wheel with blades located radially is rotated at high speed. On to

this revolving wheel, abrasive is fed in such a manner that it

travels along the radial length of the blades and then is thrown off

in a high velocity stream at the surface to be cleaned, efficiently

blast cleaning the work surface.

After the abrasive has impacted the work surface, it rebounds

back into the machine, taking the rust and old coating debris with

it. Inside the machine the abrasive is separated from the dust and

debris. The abrasive is returned to the abrasive storage hopper to

be re-used. The debris is transported by air flow into the dust

collector, where it is collected to enable it to be packaged into

containers for disposal. This process is an on-going and automatic

continuous operation.

Petrochemical Industry

In the Petrochemical industry Blastrac EBE blast cleaning machines are used as a quick and efficient

surface preparation method prior to painting small and large surfaces of storage tanks areas, for

example, the internal bottom and the external roofs of the oil storage tanks.

Because of the environment and location of storage tanks in and around oil refining sites, the blast

cleaning process must be dust free and safe.

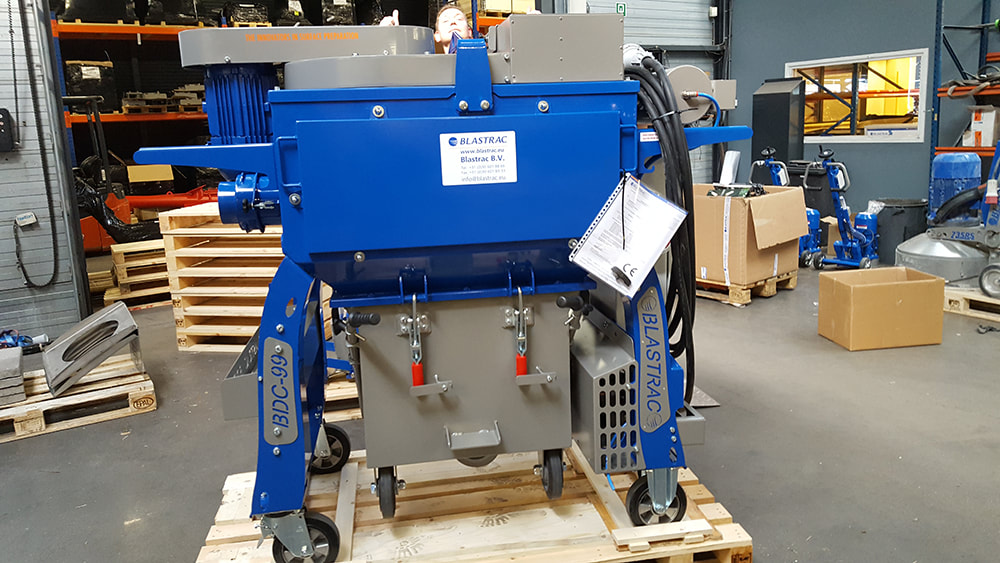

The Blastrac DEBE 350E and Blastrac D 500E Series of horizontal blast cleaning machines are

specially manufactured for the petrochemical industry. The systems are specially designed to enable

each machine to be disassembled and that the parts of the machine passed through a standard 24L /

600 mm manhole access opening into areas inside tanks that are normally inaccessible to blast

cleaning machines.

All the E Series of equipment are build according the strict safety devices that allows blasting clean

safely storage tank areas.

Shipping and Offshore Platform Industry

In the shipping and shipyard industry, horizontal blast cleaning machines are used to clean horizontal

ship decks, hatch covers and similar horizontal surfaces. The blast cleaning process can either be

carried out in the shipyard during normal maintenance programmes or at sea whilst the ship is

travelling between ports. On offshore platforms, helicopter landing decks and access walkways it is

possible to blast clean without disrupting the normal day to day working of the platform.

The machines fully comply with the very strict safety operating conditions that exist in the industry.

on vertical or near vertical surfaces. The machines are suspended from either a crane or a rigging

system and operate in an up or down direction to clean and profile steel tanks or ship hulls. They are

remotely controlled from a mobile work station.

The working principle of all Blastrac-EBE equipment is based

on the laws of kinetic and mechanical energy. The cleaning

operation is performed by steel abrasive being thrown at high

velocity against the surface to be cleaned. Throwing action is

achieved through centrifugal force, where a wheel with blades

located radially is rotated at high speed. On to this revolving

wheel, abrasive is fed in such a manner that it travels along

the radial length of the blades and then is thrown off in a high

velocity stream at the surface to be cleaned, efficiently blast

cleaning the work surface. After the abrasive has impacted

the work surface, it rebounds back into the machine, taking the rust and old coating debris with it. Inside the machine the abrasive is separated from the dust and debris. The abrasive is returned to the abrasive storage hopper to be re-used. The debris is transported by air flow into the dust collector, where it is collected and packed into containers for disposal. This process is an on-going and automatic continuous operation. A system of especially designed magnets, specifically arranged and attached to the machine, pull against the steel work surface. By this means the machine is maintained in close contact with the work surface, thus ensuring that abrasive loss and dust emissions are kept at a minimum. This allows the

machine to operate in close proximity to other process functions and follow on painting procedures can continue without loss of time.

Horizontal Blast Cleaning Machines for Steel

The dust free blast-cleaning equipment of Blastrac-EBE is especially designed for use in shipyards

and in the petrochemical industry, where its use replaces traditional open blast cleaning operations.

The working principle of all Blastrac-EBE equipment is based on the laws of kinetic and mechanical

energy. The cleaning operation is performed by steel abrasive being thrown at high velocity against the

surface to be cleaned.

Throwing action is achieved through centrifugal force, where a

wheel with blades located radially is rotated at high speed. On to

this revolving wheel, abrasive is fed in such a manner that it

travels along the radial length of the blades and then is thrown off

in a high velocity stream at the surface to be cleaned, efficiently

blast cleaning the work surface.

After the abrasive has impacted the work surface, it rebounds

back into the machine, taking the rust and old coating debris with

it. Inside the machine the abrasive is separated from the dust and

debris. The abrasive is returned to the abrasive storage hopper to

be re-used. The debris is transported by air flow into the dust

collector, where it is collected to enable it to be packaged into

containers for disposal. This process is an on-going and automatic

continuous operation.

Petrochemical Industry

In the Petrochemical industry Blastrac EBE blast cleaning machines are used as a quick and efficient

surface preparation method prior to painting small and large surfaces of storage tanks areas, for

example, the internal bottom and the external roofs of the oil storage tanks.

Because of the environment and location of storage tanks in and around oil refining sites, the blast

cleaning process must be dust free and safe.

The Blastrac DEBE 350E and Blastrac D 500E Series of horizontal blast cleaning machines are

specially manufactured for the petrochemical industry. The systems are specially designed to enable

each machine to be disassembled and that the parts of the machine passed through a standard 24L /

600 mm manhole access opening into areas inside tanks that are normally inaccessible to blast

cleaning machines.

All the E Series of equipment are build according the strict safety devices that allows blasting clean

safely storage tank areas.

Shipping and Offshore Platform Industry

In the shipping and shipyard industry, horizontal blast cleaning machines are used to clean horizontal

ship decks, hatch covers and similar horizontal surfaces. The blast cleaning process can either be

carried out in the shipyard during normal maintenance programmes or at sea whilst the ship is

travelling between ports. On offshore platforms, helicopter landing decks and access walkways it is

possible to blast clean without disrupting the normal day to day working of the platform.

The machines fully comply with the very strict safety operating conditions that exist in the industry.